In an era where logistics efficiency spells the difference between profit and loss, understanding drayage costs has never been more crucial. Often overlooked, drayage charges are a pivotal component of the shipping industry in the United States.

At Compare The Carrier, we understand the intricacies of drayage charges, from the complexities of chassis split fees to the nuances of pre-pull fees. This article, crafted by our team of industry experts, aims to demystify drayage rates and costs, providing valuable insights and strategies for businesses navigating this essential yet intricate sector. Whether you’re a seasoned logistician or a newcomer to the field, our guide is designed to arm you with the knowledge needed to optimize your container shipping operations and reduce expenses, leveraging our expertise in the industry.

The Evolution of Drayage in the US

Remember the old Western movies, where burly guys wrestled crates onto horse-drawn drays at bustling ports? Well, times have changed, and drayage – the short-distance hauling of cargo – has gone through a fascinating transformation in the US. From sweat-stained beasts of burden to sleek semi-trucks humming with technology, let’s take a ride through drayage’s history and see how it impacts those ubiquitous “Made in China” labels gracing store shelves.

From Haylofts to Highways: The Horsepower Revolution

In the early days, drayage was all about muscle. Strong horses pulling sturdy carts were the backbone of moving goods around docks and rail yards. It was a tough job, demanding long hours and brawn to navigate muddy streets and uneven terrain. But hey, at least you got some fresh air!

The 20th century brought a game-changer: the internal combustion engine. Trucks replaced horses, transforming drayage into a faster, more efficient operation. But hold your horses (pun intended)! These weren’t the streamlined rigs we see today. Early trucks were clunky and unreliable, often sputtering to a halt, leaving cargo stranded and tempers flaring.

Intermodal Magic: Containers Change the Game

The introduction of shipping containers in the 1950s was another major turning point. These standardized metal boxes revolutionized global trade, allowing easy transfer between ships, trucks, and trains. Suddenly, drayage became part of a bigger, smoother flow of goods across continents.

The Price We Pay: Demystifying Drayage Costs

Drayage, the often-murky last leg of your shipment’s journey, can harbor hidden cost monsters. Fear not! This guide sheds light on the key drivers and hidden fees, empowering you to navigate drayage costs like a pro.

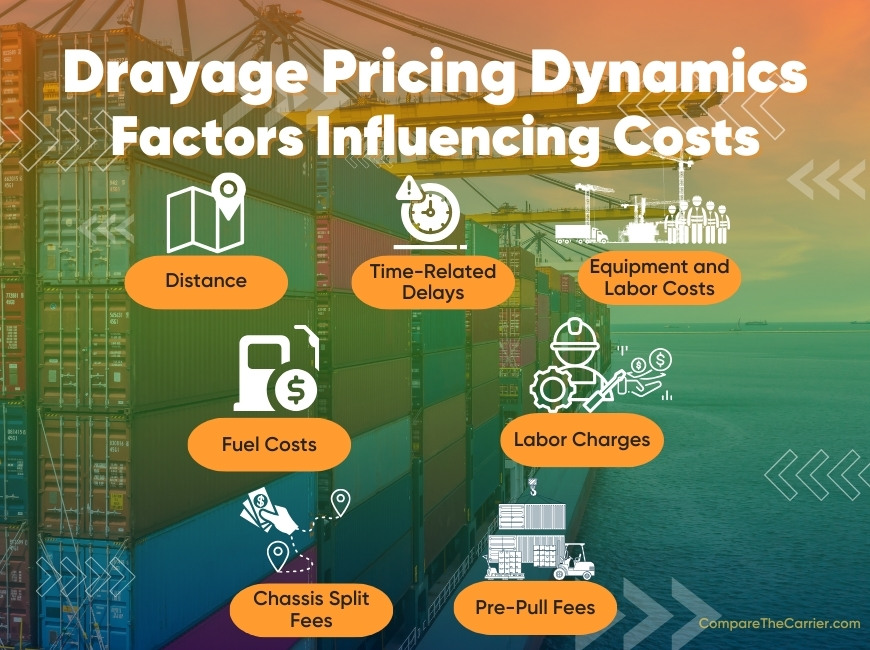

The Core Cost Drivers:

Beyond the Base:

Your base rate is just the tip of the iceberg. But the base rate can be 40-60% of your total cost. Negotiating even a small reduction yields significant savings, especially for regular or bulk shipments. Dive into accessorial fees, the hidden cost culprits:

Conquering the Cost Maze:

Knowledge is power! Here’s how to manage drayage costs effectively:

Drayage costs, once a mystery, now stand demystified. By understanding the key factors and employing these strategies, you can navigate this crucial transport leg with confidence and control.

Tech Takes the Wheel: The Future of Drayage

The future of drayage is all about efficiency and transparency. Technology is playing a starring role with:

Whether you’re a business owner importing goods or a consumer waiting for that online purchase, drayage is the invisible hand that keeps the wheels of American commerce turning. Understanding its evolution, costs, and future trends gives you a deeper appreciation for the complex journey your next Amazon package takes before reaching your doorstep.

So next time you see a truck rumbling down the highway, remember, it’s not just carrying metal boxes. It’s carrying the story of American ingenuity, adaptation, and the relentless pursuit of a smoother, faster, and more cost-effective way to deliver the goods that keep our lives humming.

Understanding Drayage Costs

Drayage, an essential yet often underappreciated aspect of the shipping industry, involves specific costs that can significantly impact the overall logistics budget. Understanding these costs is crucial for businesses to plan and execute cost-effective shipping strategies.

Drayage Charges: The Basics

Drayage charges encompass the fees associated with transporting freight over a short distance, typically within the same metropolitan area, and especially in and out of ports, rail terminals, or warehouses. These charges are influenced by several factors, including:

Key Components of Drayage Costs

Understanding the breakdown of drayage expences is critical for businesses to identify areas where they can optimize and save. These costs include:

By comprehensively understanding and strategically managing these components, businesses can significantly reduce their overall spend on drayage, making their logistics operations more efficient and cost-effective. At Compare The Carrier, we specialize in providing insights and solutions tailored to optimizing these aspects of drayage, ensuring our clients navigate the complexities of these charges with ease and efficiency.

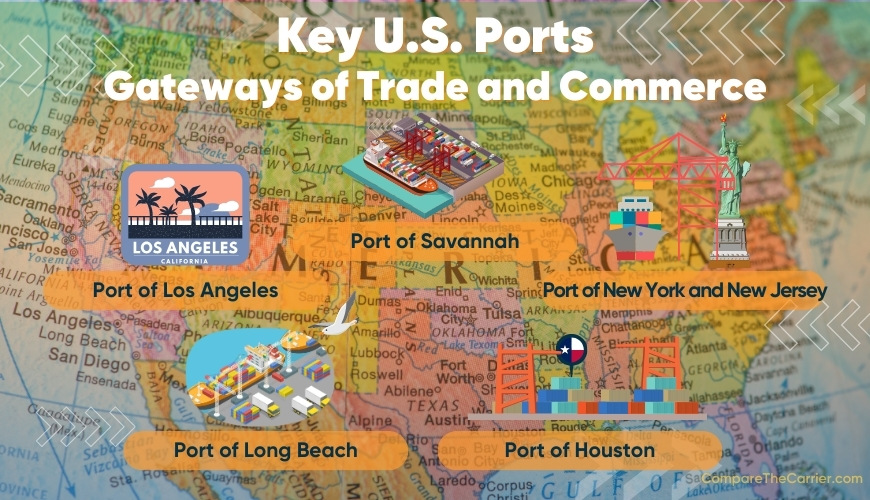

Comparing Drayage Quotes Across Key US Ports

Drayage quotes can vary significantly across different ports in the United States. This variance is due to a multitude of factors including port size, congestion levels, local regulations, and the availability of drayage service providers. Understanding these differences is crucial for businesses that rely on maritime shipping and logistics.

Key US Ports and Their Drayage Cost Dynamics

Each of these ports presents its own set of challenges and opportunities in terms of drayage costs. Businesses must consider these unique factors when planning their shipping and logistics operations to optimize costs.

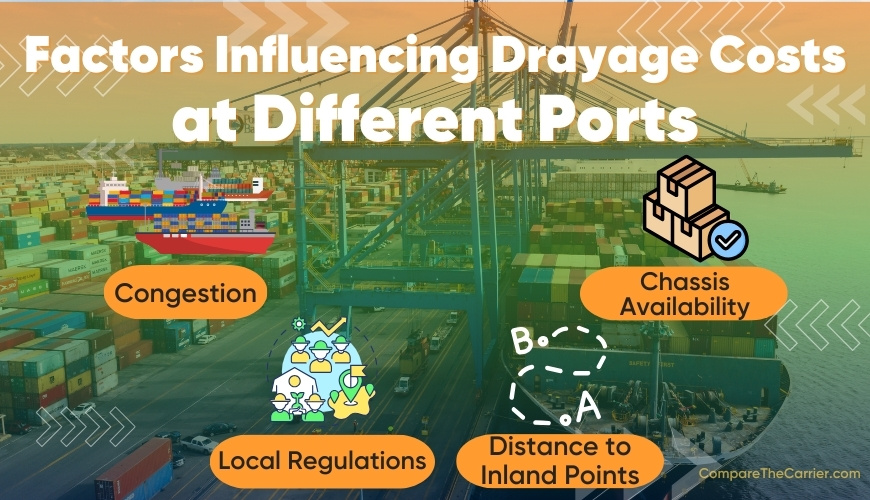

Factors Influencing Drayage Costs at Different Ports

The interplay of these elements highlights the importance of a tailored approach to managing drayage costs. Recognizing how each factor impacts different ports is key to effective cost management in logistics.

Drayage costs across key US ports are subject to a complex mix of local and logistical variables. From the congestion at major ports like Los Angeles and New York to the more streamlined operations at ports like Savannah, each location presents unique cost considerations. Businesses must navigate these variables with a strategic approach, informed by an understanding of the specific dynamics at play. In this landscape, Compare The Carrier stands as a crucial partner, offering insights and expertise to help businesses effectively manage their drayage expenses and optimize their overall logistics strategies.

Impact of Regulations on Drayage Expenses

In the intricate tapestry of the US shipping industry, regulations play a pivotal role in shaping drayage prices. These regulations, often designed for safety, environmental protection, and fair trade practices, can significantly impact the way drayage services are priced and managed.

Key Regulations Influencing Drayage Price

Environmental Regulations:

Labor Laws and Driver Regulations:

Safety and Transportation Regulations:

The Ripple Effect of Regulations on Drayage Quotes

The landscape of regulations surrounding drayage services is a key driver in determining drayage costs. While these regulations aim to ensure safety, fairness, and environmental stewardship, they also bring about changes in the operational and financial aspects of drayage services. For businesses navigating this landscape, staying informed about current and upcoming regulations is essential. It enables them to anticipate changes in drayage rates and adjust their logistics strategies accordingly.

Strategies for Optimizing Drayage Costs

In the competitive realm of logistics and shipping, effectively managing drayage costs is key to maintaining a lean and profitable operation. Here are practical strategies that businesses can employ to optimize these costs, which include drayage charges, drayage rates, chassis split fees, and pre-pull fees.

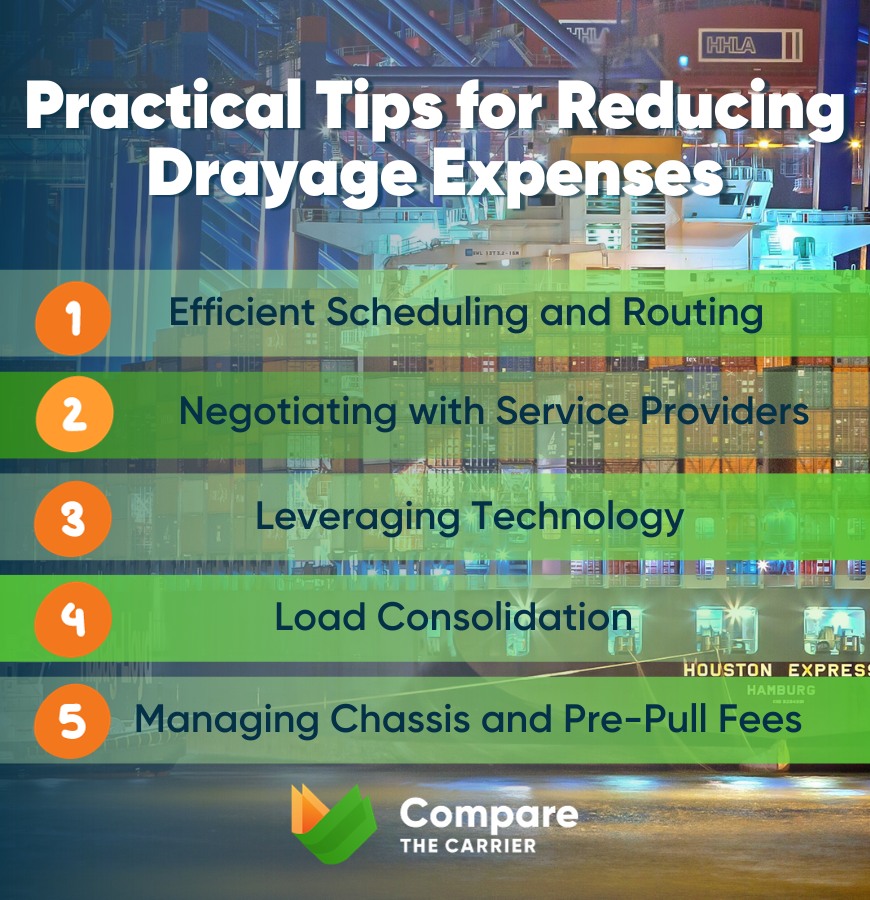

Practical Tips for Reducing Drayage Expenses

1. Efficient Scheduling and Routing:

2. Negotiating with Service Providers:

3. Leveraging Technology:

4. Load Consolidation:

5. Managing Chassis and Pre-Pull Fees:

Optimizing drayage rates and fees requires a multifaceted approach, combining efficient planning, smart negotiation, technology use, and effective load management. By implementing these strategies, businesses can significantly reduce their drayage-related expenses, enhancing their overall operational efficiency.

Navigating the intricacies of the cost of drayage in the US shipping industry is a complex but essential task for businesses involved in logistics and transportation. From understanding the evolution of drayage in the US to comparing drayage costs across key ports, and considering the impact of regulations and strategies for cost optimization, this comprehensive guide has aimed to provide a clear and informative overview.

Armed with this knowledge, companies can make more informed decisions, optimize their operations, and effectively manage their drayage expenses. At Compare The Carrier, we are committed to aiding our clients in this journey, providing expert insights and solutions tailored to the unique challenges of drayage in the shipping industry.

Remember, effective management of drayage costs is not just about cutting expenses – it’s about enhancing overall efficiency and competitiveness in a dynamic global market of container drayage.

FAQ

How are drayage costs calculated?

Drayage costs are typically calculated based on the distance traveled, the time taken (including waiting and loading times), the type of cargo, and the specific requirements of the transport (like chassis usage).

What is a chassis split fee in drayage?

A chassis split fee is a charge that occurs when a shipping container’s chassis (the wheeled frame) is picked up at one location and returned to another. This fee compensates for the extra handling and logistics involved.

Can drayage rates vary significantly between different ports?

Yes, drayage rates can vary widely between ports due to factors like congestion, distance to the final destination, and local labor costs.

Are there any strategies to reduce drayage costs?

Yes, strategies include efficient scheduling to avoid waiting times, negotiating with carriers, using technology for route optimization, and consolidating loads to maximize container usage.

How do environmental regulations affect drayage costs?

Environmental regulations, especially those requiring low-emission vehicles, can increase operational costs for drayage providers, which may be passed on to customers as higher rates.

Why is understanding drayage costs important for businesses?

Understanding drayage costs is crucial for budgeting and cost control in the logistics process. It helps businesses optimize their supply chain and reduce unnecessary expenses.